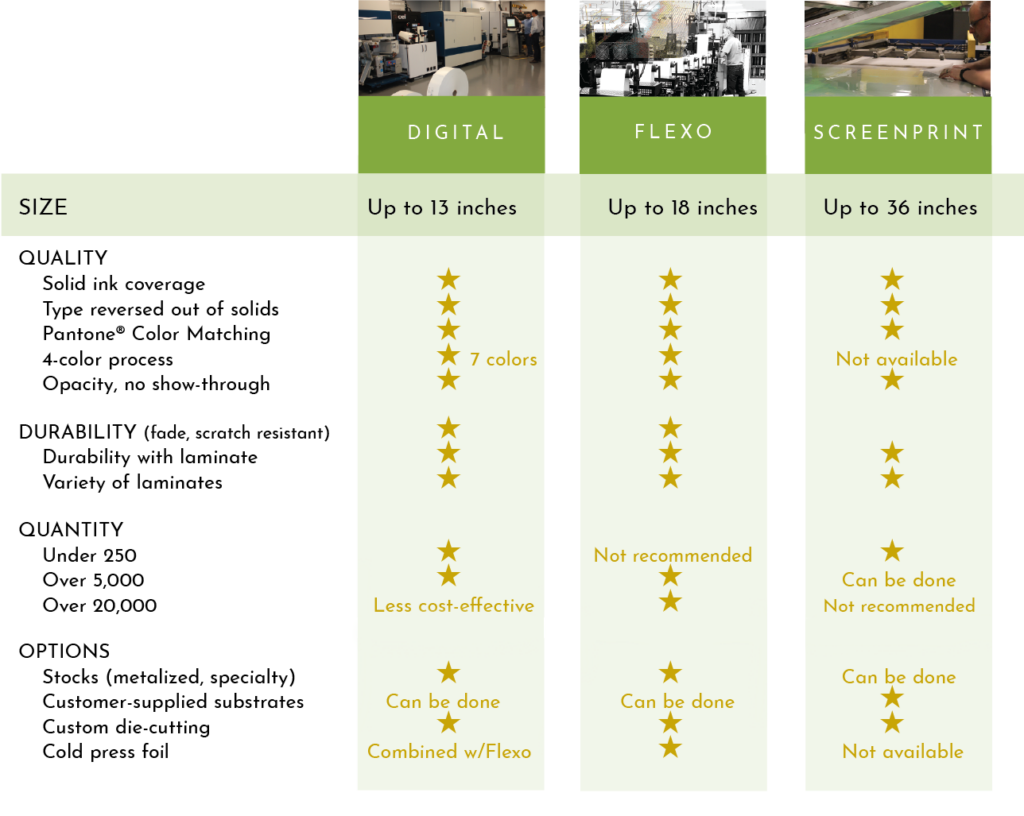

Amherst Label offers three top-quality printing technologies. With digital, flexographic and screen printing under one roof, we aim to meet all your specialty printing needs. In addition, our hybrid digital flexo press combines the advantages of both technologies in one process. Click to enlarge our chart comparing each process’s features.

Digital label printing

Digital technology allows for quicker set-ups and changeovers, which makes it the more cost-effective choice on small runs in many cases. Updating art is quicker and easier because plates don’t need to be created in order to print. Expanded gamut printing tops CMYK with Orange and Violet to allow us to print a wider spectrum of color than previously possible in digital printing. Variable Data Printing is also available, as well as printing alternating versions of a label on the same roll. Game-changing!

Our Domino N610i 7-color UV Digital Press is a technological leap forward in label printing.

Competitive pricing, especially in quantities under 5,000, plus superior quality and speedy delivery.

- 13” max print width

- 247 ft/minute

- Special UV ink set. Prints CMYK, Orange, Violet, two hits of opaque white

- White opacity is “like screen print”

- Highly durable UV ink is moisture resistant

- Variable Data Printing (VDP) in black ink for barcodes, numbering, etc.

- Two die stations: semi rotary/full rotary

- Laminate on front and back in same pass

- More affordable in smaller quantities!

Digital/Hybrid label printing

Our two Domino MPS Digital Hybrid presses combine the best of digital and flexographic printing. With several flexo print stations and multiple die cutting stations, we can now combine CMYK+OV digital print with spot inks, cold foil, variable data, and we can even print on the liner, all while die cutting in-line!

Digital, Flexographic and Screen Printing

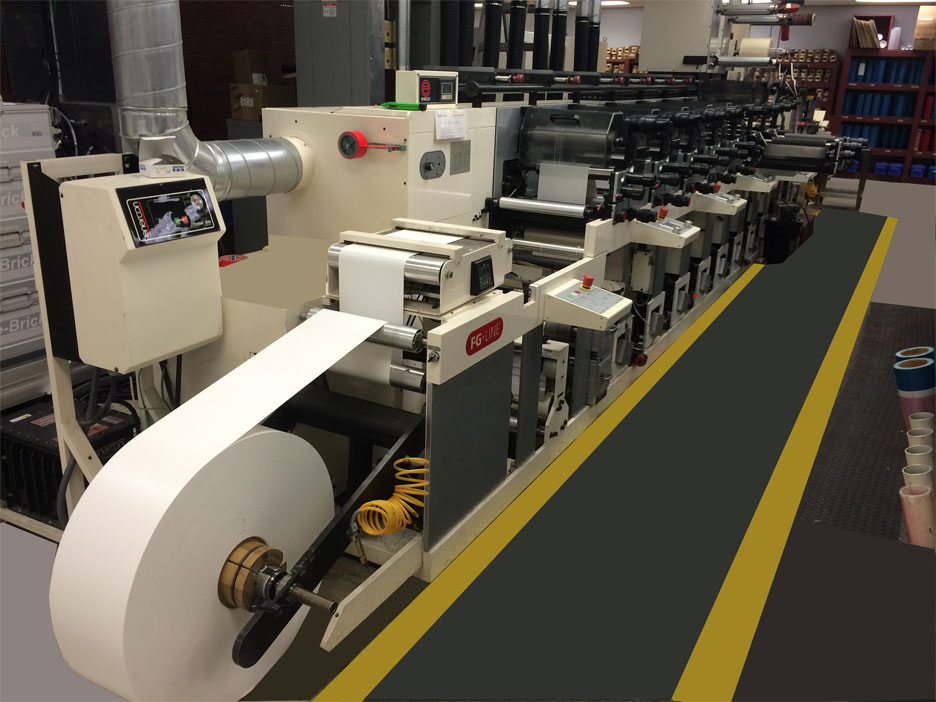

Flexographic label printing

The in-line flexography printing and die-cutting process allows Amherst Label to create high-quality labels on a wide variety of materials, including paper, film and foil surfaces.

OUR FLEXOGRAPHIC EQUIPMENT

13″ Nilpeter press – Eight colors, UV and waterbased ink capabilities. Finished label size up to 13.25” x 25”, 3 die cutting stations. Labels can be produced on rolls, sheeted or fanfolded. Material range from .001” (25 microns) to .010” (250 microns) including unsupported films, tag stocks and pressure sensitive materials. Press is equipped with auto registration, corona treating, video web inspection and web cleaning. Can do cold foiling, laminating, and back side printing.

18″ Propheteer press – 8 colors including 1 UV station and 2 stations for back printing. 4 die cutting stations. Finished label size up to 18” x 24”. Labels can be supplied on rolls, fanfolded or sheeted. This press has pinfeed, hot stamping and laminating capabilities and an automatic registration unit with video web scanner for excellent registration.

10″ Propheteer press – 6 and 7 colors including 1 UV station. There are 4 die cutting stations on each press. Finished label size up to 10” x 15”. Labels can be supplied on rolls, fanfolded or sheeted. UV protective varnish or over lamination plus 1 UV ink print-station. System includes a turn-bar for back side printing. Can do cold foiling and print on adhesive. The 7 color press has a PC Industries 100% Web Inspection system giving us the ability to inspect every label as it is produced.

Digital, Flexographic and Screen Printing

Screen print labels

The process of screen printing is believed to date back as far as 960 AD. This versatile technique uses layers of durable ink to create clean and intricate designs. At Amherst Label, we offer a wide variety of materials and die-cutting abilities to assure that the finished product will meet your specific label printing requirements. We have years of experience working with engineering drawings to create art for logos and machine plates.

- Subsurface printing on 5 mil, 10 mil, 15 and 20 mil Lexan®

- Various sizes and shapes for recessed areas

- Material selection including durable vinyl

- Low Surface Energy Adhesives for powder-painted surfaces

- 3M® adhesives including 467, 468, 9741

Click for more info about our screen printed products.

CONTACT US FOR MORE INFORMATION OR A QUOTE

Printing Industries of New England award winner 2020

Tag & Label Manufacturers Institute Innovation Award

Amherst Label owner Nick Calvetti was named Business Leader of the Year 2019 Greater Merrimack Chamber of Commerce