Time is the X factor in label manufacturing.

There are many factors in producing the ideal label: material, ink, varnish/lamination, etc. But after all of those boxes are checked, the X factor is time.

When is the label needed? Really needed. Can the order come in two weeks before that? Three weeks before that? The Amherst Label team—everyone on the team— believes in getting customers what they need, when they need it. Once we make a commitment, all systems are go in trying to hit the mark.

Sharing your drop-dead/gotta-have-it-or-all-progress-comes-to-a-screeching-halt need-by date with us is helpful.

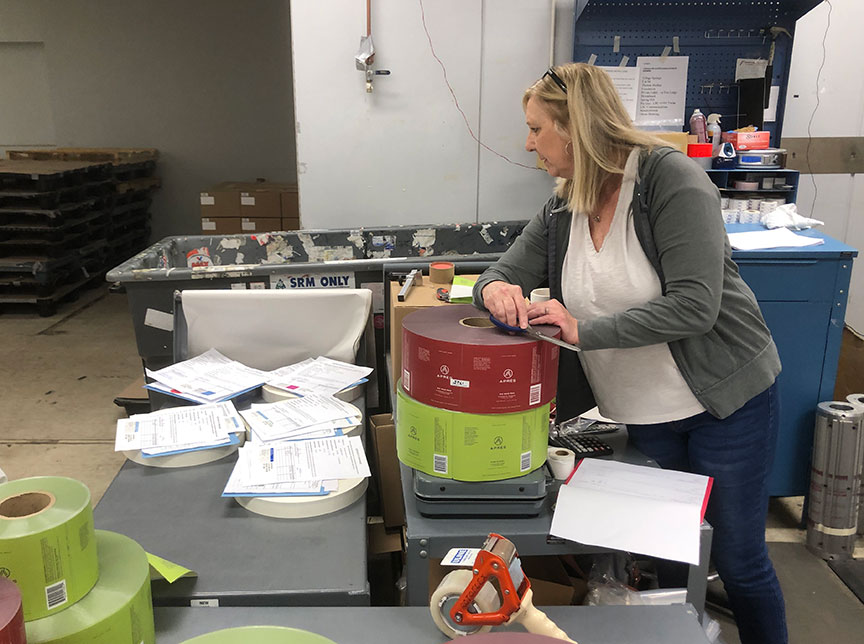

The other thing about time is that each step of the label manufacturing process needs some. Procurement and allocation of stock is step one. Art prep is a step. Proofing is a step. The amount of time it takes to get a proof back is a step that customers can really help shorten. But rushing the proofing step isn’t strategic. In fact, rushing any step isn’t good business in the long run. The intricacies of the label manufacturing process are best done in a step-by-step, systematic way.

Time is the X factor in allowing the process to flow smoothly, without jamming, rushing, and stressing.

How much time allows the system to work best? That is the $million question. Our press operators love uptime and are happiest when they are producing. But the chances are that each day something will interrupt the flow. Recognizing that we don’t live in a perfect world, time helps everyone. Especially our customers.

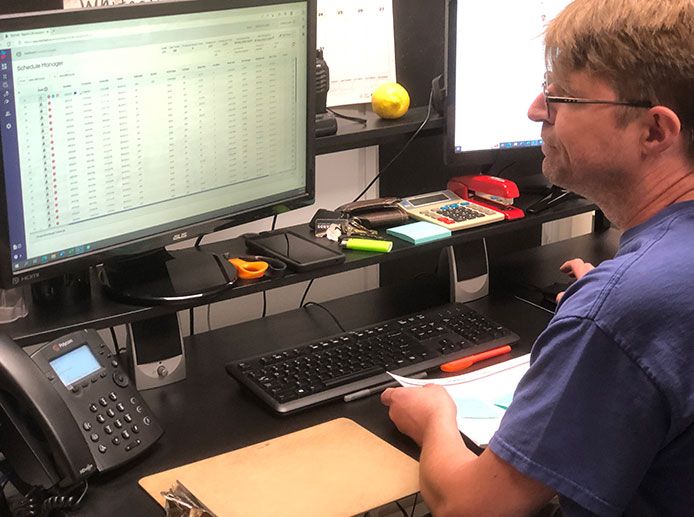

What is the ideal amount of lead time? Even Jim Cutler, our Operations Manager, who has seen it all and “knows a thing or two” about label production, can’t answer the question definitively. Here’s his best attempt:

“For screenprint jobs, ten days should be fine.

“For flexo jobs, if it’s a reorder and we have the plates, ten days should be fine. We want to keep our flexo presses busy.

“But for new orders requiring special stocks or new dies, even ten days can be rough.”

It is probably safe to say that the longer the lead time, the better, with two full weeks the standard.

In conclusion, here’s Jim’s suggestion:

“Conferring with your Account Exec or Sales Coordinator about your real need-by date is THE biggest help.”

Conferring with your sales rep, who then checks in with our Scheduler and Purchasing Manager, who may check in with our Digital, Flexo or Finishing team, is the best starting place. It really does “take a village” to produce a label.

Working together, with time on our side, anything is possible.

2 thoughts on “Time helps”